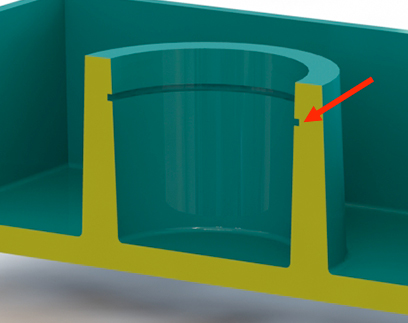

Draft

Draft is a slight angle or taper designed into the sides of your part that allows it to be extracted from a mold more easily. Draft angles typically range from 1 to 3 degrees and slope.

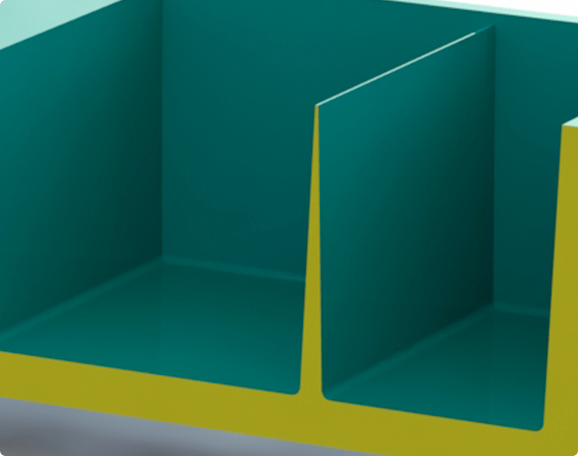

Undercuts

Undercuts are areas on a part that prevent the part from being ejected from the mold. When designing parts for injection molding, it is important to avoid undercuts or minimize them as much as possible. Undercuts require additional mold components and can increase tooling complexity and cost. If undercuts are necessary, they can be designed to be collapsible, which will allow the part to be ejected from the mold.

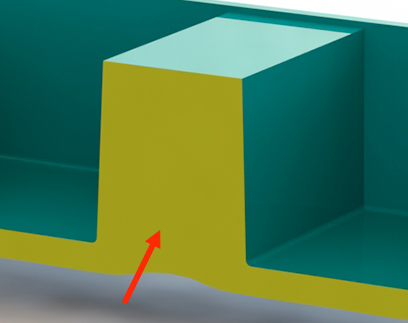

Wall Thickness Variation

Consistency in wall thickness is crucial in injection molding. Variations in wall thickness can result in uneven cooling and warpage, which can affect the part’s structural integrity and dimensional accuracy. Avoiding wall thickness variation can minimize the need for additional mold components, which can reduce tooling complexity and cost.

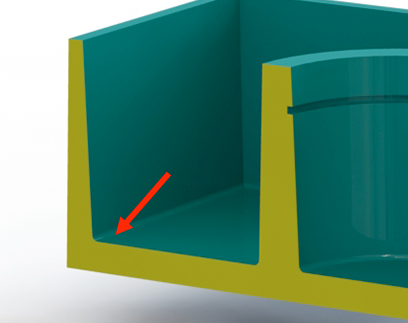

Rounded Corners

Sharp corners can create stress points in injection molded parts, which can lead to cracking or breaking. To avoid these issues, it is recommended to design parts with rounded corners. Rounded corners can also reduce stress on the mold, which can increase tooling longevity.

Small Features

Small features, such as thin walls or small details, can be challenging to mold accurately. These features require precise tooling and can increase tooling complexity and cost. To minimize tooling complexity and cost, it is recommended to design parts with larger features that are easier to mold accurately.

Undercuts

Undercuts are areas on a part that prevent the part from being ejected from the mold. When designing parts for injection molding, it is important to avoid undercuts or minimize them as much as possible. Undercuts require additional mold components and can increase tooling complexity and cost. If undercuts are necessary, they can be designed to be collapsible, which will allow the part to be ejected from the mold.