Injection Molding

Made Easy ✓

With more than 20 years of experience in injection molded devices, components, and packaging, our skilled team of designers and engineers collaborates closely with you at every stage to turn your product vision into reality as accurately, swiftly, and efficiently as possible. We are dedicated to providing the highest level of professional support for any injection molding project, regardless of size or complexity.

Specialties

﹢ Parts Decoration

﹢ Functional Parts

﹢ Overmolding

﹢ Assembly and Kitting

﹢ Insert Molding

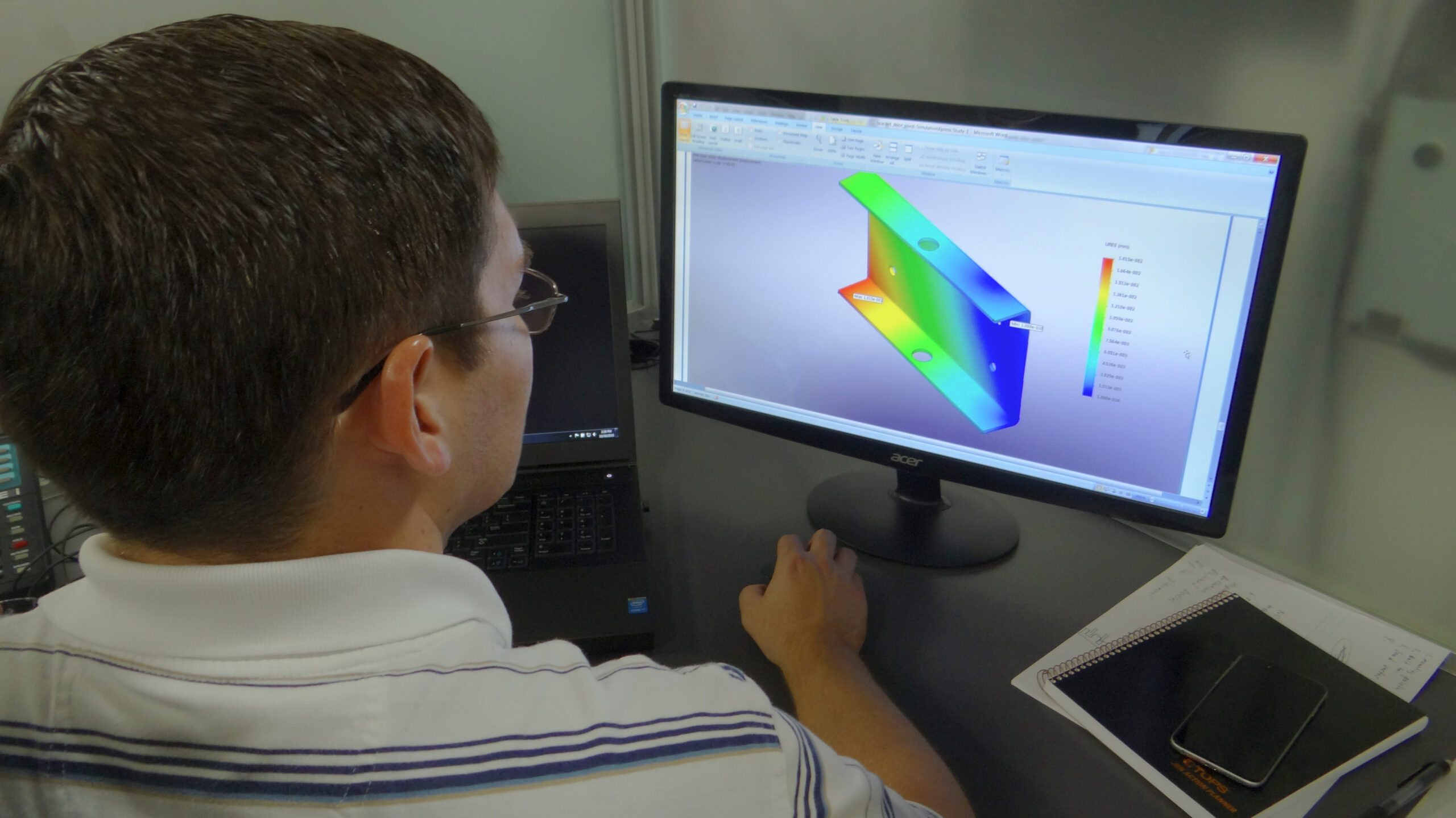

Capabilities

﹢ Injection Molding

﹢ 3D Printing

﹢ Design

﹢ Prototyping

﹢ Engineering

﹢ Production

Markets

﹢ Industrial

﹢ Aerospace

﹢ Specialty Automotive

﹢ Lawn & Garden

﹢ Commercial & Residential Appliance

If you’re ready for a quote, we’re ready to help!

Get Inspired With Our FREE Sample Package

Our sample package includes 10 custom sample options showcasing the diverse materials and finishing techniques that can take your product to the next level!